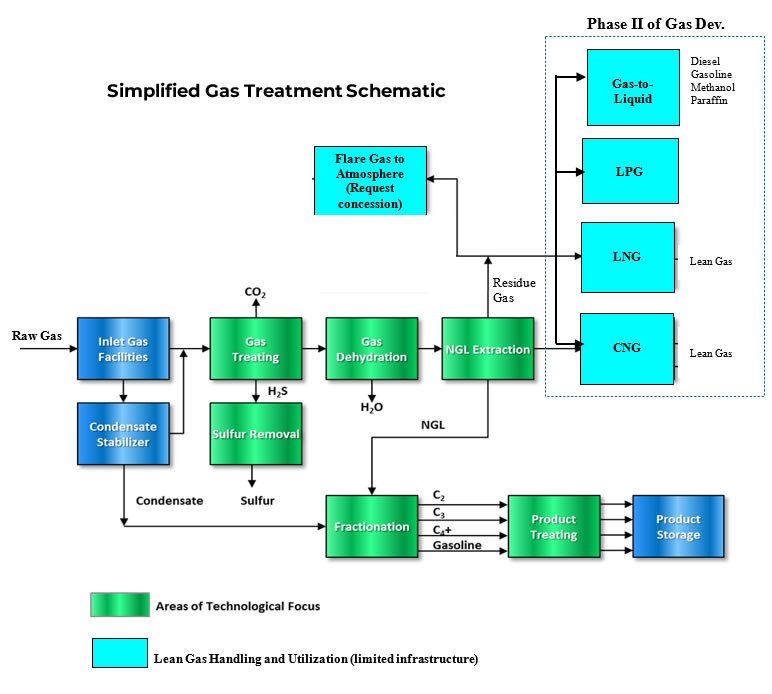

Westflux Integrated Service Limited is set up as a midstream energy company with the objective of developing, installing and operating gas processing and handling facilities with capacities up to 50 MMSCFD. We are focused on designing and installing modularized gas processing plants that are easy to mobilize and demobilize, as gas production ebbs. We have experts in the field of gas processing and handling with decades of experience.

Our access to state-of-the-art equipment and advanced technology allow us to process a wide variety of natural gas compositions, into several end products such as liquefied petroleum gas (LPG), compressed natural gas (CNG), gas-to-liquids (GTL) , liquefied natural gas (LNG), etc.

We have deep relationships with OEMs that puts us in a position to source for, develop and install the following types of gas handling technologies

GAS LIQUID (LPG/NGL) EXTRACTION:

LPG which stands for Liquefied Petroleum Gas is a mixture of propane and butane (or just one of these hydrocarbons), which are both gases at normal temperatures and pressures but can be liquefied under moderate pressure or cooling. It is extracted from natural gas fields during natural gas processing through a process called fractional distillation, and can also be extracted from crude oil during the refining process.

MODULAR COMPRESSED NATURAL GAS (CNG)

Unlike traditional large-scale CNG storage and distribution systems, modular systems are designed to be more flexible, scalable, and suited for various applications. They can be easily deployed, relocated, and expanded based on demand. Natural gas is compressed to a high pressure (typically 3,000 to 3,600 psi or 200 to 250 bar) to reduce its volume for storage and transportation.

GAS TO LIQUID (GTL)

Gas-to-Liquid (GTL) technology involves converting natural gas into liquid fuels and other products. This process typically uses two main stages: gas reforming and synthesis. Natural gas is first converted into syn-gas (a mixture of hydrogen and carbon monoxide), which is then processed through a Fischer-Tropsch synthesis to produce liquid hydrocarbons, including diesel, naphtha, and other chemicals.

LIQUEFIED NATURAL GAS (LNG)

Liquefied Natural Gas (LNG) is natural gas that has been cooled to a liquid state at approximately -160°C (-260°F). This process reduces the gas’s volume by about 600 times, making it more efficient to store and transport over long distances. LNG is primarily composed of methane (CH₄), but can also contain small amounts of other hydrocarbons.

LEAN GAS

Lean Natural gas C! C2 is a naturally occuring hydrocarbon gas mixture consisting primarily of methane and ethane.

The heat energy of C1 C2 lean Gas is measured by units of calorific value, which is defined by number of heat units released when a unit volume of gas burns. Typicak units of calorific value are British thermal units (Btu), Joules (J), and Kilocalories (Kcal).

Worldwide, the cost of C1 C gas to customers is commonly specified in MMBtu (Million British Thermal Unit), MMSCF ( Million Standard Cubic Feet), SCN ( Standard Cubic Meter).

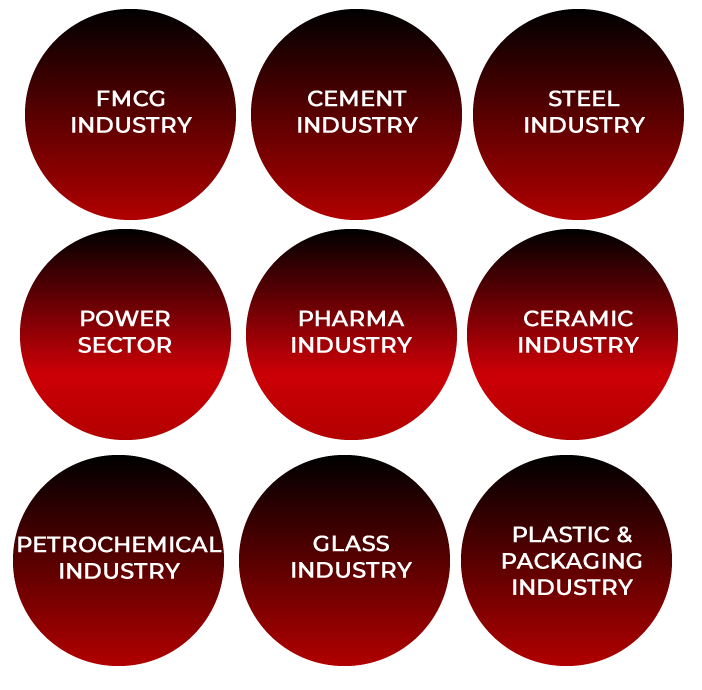

Industries that use C1 & C2 Lean gas

Food & Beverages Industries

Steel Industries

Power/Cement Factories

Pharma Factories

Ceramic Factories

Chemicals Factories

Glass Factories

Plastic & Packaging Factories